We had an unwelcome surprise a few weeks ago when we discovered a small leak in our holding tank. It was on the top so it leaked air mainly but still was not good.

For those that are lucky enough to not be familiar with holding tanks, they do what the name suggests, they hold stuff. In this case, our waste–human waste. The holding tank is connected to our toilet, so all the toilet waste goes into the tank. From there we can pump it out at marinas or overboard if we are out at sea. Having a leak in the holding tank is not a good thing. You might say, it stinks.

Thankfully, our leak was on the top of the tank and the waste rarely reaches the top. Still, it needed to be fixed.

To fix it we first cleaned the tank very well and then sanded around the hole with 60 grit sandpaper. I started the job but Sharlene took over and before I knew it, she had it looking as shiny as new. From there we used JB Weld Steel which is an epoxy putty that bonds well to stainless steel. Voila, problem solved! Wrong.

Unfortunately, the JB Weld worked but as we sealed one hole, we found several more pinholes had appeared. We’d fix those and discover others. We were playing Whac-A-Mole with our holding tank! It was time for a new tank.

We couldn’t find any off the shelf tanks that would fit the space we had so after doing some research we chose a company in Tauranga to make our new tank. Drawing on the drafting skills I learned in grade 8, I sent drawings back and forth to the manufacturer and eventually settled on a final design. Three weeks later our tank was delivered to us in Whangarei.

After a couple of hours, we had the old tank out and disposed of. The new one was in place, connected and working perfectly. Well, that’s how I imagined it would go.

Like most jobs on boats, it didn’t go smoothly. Well, it did but it just took longer than planned. The tank removal and installation required removing some of the joinery in the forward cabin. The woodwork was held in place by a handful of screws but the screw heads were either stripped or painted over. Between carefully chipping the paint out of the screw heads and a couple of trips to the tool shop for the right set of screw extractors, it took the better part of a day to remove the joinery.

While we had everything apart, we decided to replace the waste hoses that weave around and behind things connecting the toilet to the tank and the tank to where the waste can be disposed of. Doing this while avoiding dripping human waste into the unreachable nooks and crannies of the boat required some careful planning, ample use of plastic bags and several meters of duct tape. Additionally, we had a spray bottle of bleach at the ready should it be necessary.

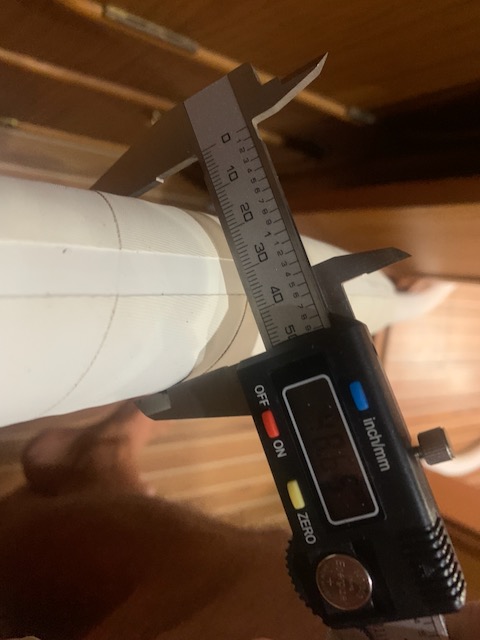

When purchasing the new hose we decided to upgrade to the top quality (read top dollar) “no odour” variety. It seemed like a good idea in the shop. However, once we started installing the new hoses, we discovered that the outer diameter of the new hose was a few millimetres larger than the old hose. This meant that the existing holes throughout the nether regions of the boat were too small. Of course we didn’t discover this problem until we were pulling the fourth and final hose. Perhaps we should have removed all the hose, recut the holes and then run the hoses again but we’d already spent a couple of days pulling hoses so we didn’t have the energy–both physical and mental–to start again. Instead, with some creative use of a drill, a chisel, a hacksaw blade and a file, we managed to enlarge the holes just enough to get the last hose through.

Thankfully the job is done. The tank is installed. The new hoses are run.

We filled the new tank with fresh water and pumped it out. It works though we are reticent to use it. We were at a marina when we installed it so we didn’t need to use it. Now we are on passage to Fiji so we still don’t need to use it. Perhaps we should stay on passage so we never need to use it. Like Bernard Moitessier at the end of the first Golden Globe Race, we could divert from our planned destination and just keep going. We could continually circle the globe, never stopping and never needing to use our new holding tank.

What an ordeal! So very glad it was a successful installation in the “end” – a huge relief, I’m sure! but… please don’t “keep going” – LOL! 😜. We are very much looking fwd to seeing you back here on our Cdn Coast in July! Almost 2 months to go to the “big” celebration! 💕

LikeLike

We decided to stop in Fiji 😃 The wedding is not far off now!

LikeLike